Quality CNC Manufacturing

Ik ben Mark, jouw inkoop specialist.

Ik help je graag bij de inkoop van jouw kwaliteit CNC onderdelen.

Ons algoritme raadpleegt de meest passende leveranciers.

Ik stuur je vervolgens een offerte op maat binnen 48 uur.

Je kunt hieronder eenvoudig starten met je aanvraag.

En dan online je orders bekijken, accepteren en volgen.

Allemaal binnen in één slim dashboard.

Of je nu een spoedlevering nodig hebt.

De productie van een kleine serie onderdelen start.

Of je inkooprisico wilt spreiden met ons wereldwijde netwerk.

Batchforce biedt de oplossing mét garantie in kwaliteit.

Jouw CNC productie inkopen via onze wereldwijde supply chain. Allemaal inzichtelijk in één slim dashboard van Batchforce™.

- Direct inkopen, binnen 4 weken leveren.

- Professioneel sourcen van 1 tot 1.000+ CNC onderdelen.

"*" indicates required fields

Quality CNC Manufacturing.

Jouw CNC productie inkopen via onze wereldwijde supply chain. Allemaal inzichtelijk in één slim dashboard van Batchforce™.

- Direct inkopen, leveren binnen 4 weken.

- Van 1 tot 1.000+ CNC onderdelen.

- Inloggen en registreren via je Desktop.

"*" indicates required fields

Medical Equipment

en Tools

Batchforce werkt samen met toonaangevende fabrikanten van medische apparatuur, medical start- en scale-ups, en onderzoekscentra om prototyping te versnellen en de productiecapaciteit dynamisch te schalen.

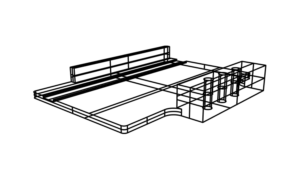

Machinery en

Agro-Food Equipment

Het Batchforce partnernetwerk biedt kritische productieflexibiliteit en maakt gebruik van Ai technologie om de kwaliteit en beschikbaarheid van elke leverancier optimaal te benutten en continu te verbeteren.

Hardware en

Electronics

Producten aanvragen in verschillende materialen en afmetingen binnen één slim dashboard. Batchforce geeft productontwikkelaars en ingenieurs de mogelijkheid om productie te managen in elke fase van de ontwikkeling.

Wij zijn niet je doorsnee leverancier, wij zijn je collega.

De relatie tussen mens en machine is in rap tempo aan het veranderen. Wij hebben daarom ons digitaal platform en algoritme gebouwd om jou te helpen.

![]()

- Vraag je CNC productie online aan.

- Overleg met onze dedicated specialisten.

- Gebruik onze data en kennis om de juiste inkoopbeslissing te maken.

![]()

![]()

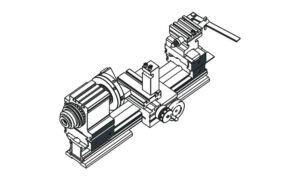

CNC draai- en

freeswerk

Batchforce ondersteunt de verspaningstechnieken draaien en frezen. Welke techniek gebruikt zal worden om jouw producten te maken hangt af van het ontwerp, de toepassing en de complexiteit.

Staal, aluminium

RVS, kunststoffen & meer

Voorbeelden van materialen die bewerkt kunnen worden zijn staal, aluminium, roestvast staal en kunststoffen. Wanneer gewenst kunnen verschillende oppervlaktebehandelingen geselecteerd worden voor jouw producten.

STEP bestanden

volgens ISO 10303-21

Batchforce maakt gebruik van STEP bestanden, deze opbouw is vastgelegd in ISO 10303-21. Zo weten we dat het bestand aan strenge eisen voldoet en voorkomen we dat er nare verrassingen kunnen optreden.

CASE STUDY

Batchforce achter de schermen van Innolux.

De meeste toeleveranciers in de metaalsector zijn vaak niet ingesteld op het snel produceren en leveren van kleine series onderdelen. En laat dat nu net cruciaal zijn in de prototypingfase van de beeldschermen die Innolux ontwikkelt.

CORPORATE CNC PROTOTYPING AUTOMOTIVEIATF 16949

De toekomst van de maakindustrie is digitaal, online en powered by data.

Sinds 2015 heeft Batchforce voor inkopers en engineers de digitale toegang gecreëerd tot een wereldwijd aanbod van kwaliteit CNC productie.

![]()

![]()

Start met Batchforce

- 2.800+ inkopers in Nederland en België.

- 100.000+ onderdelen geleverd.

"*" indicates required fields