Convert DWG file to a STEP file

Why doesn’t Batchforce online cnc service accept .DWG, DXF or other file formats and why is only a .STEP file accepted?

A STEP file is a widely used file format to exchange a product or design between different 3D programs.

The name is an abbreviation of “STandard for the Exchange of Product model data” .

But the main reason why we prefer to work with .STEP files is the fact that the structure of the STEP file is defined in ISO 10303-21.

This way we know for sure that the file meets strict requirements and we avoid nasty surprises.

Many manufacturers and suppliers who make their articles available in a 3D file choose STEP files.

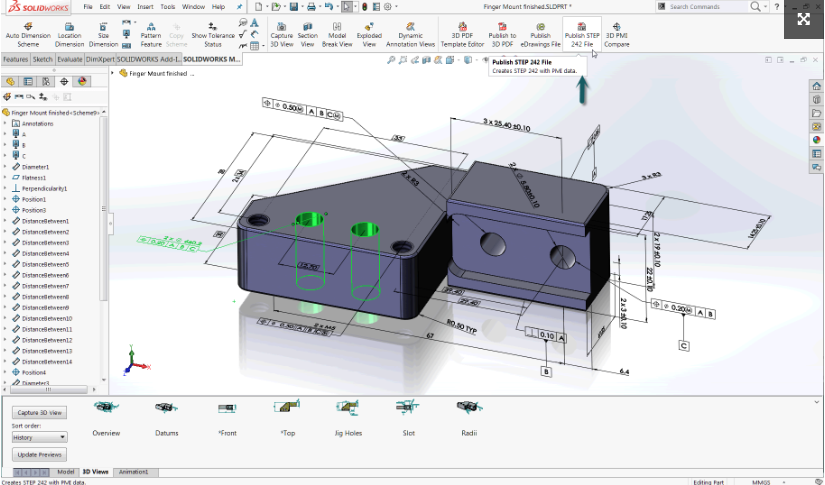

The most commonly used technical drawing programs can export 3D models to a STEP (.stp or .step) file.

They can also import a .stp or .step file and convert this file to their own desired file format.

Programs that can create and view a STEP file:

-

Autodesk Inventor from Autodesk

-

CATIA from Dassault Systèmes

-

Cobalt from Ashlar-Vellum

-

CoCreate from Parametric Technology Corporation

-

FreeCAD from Juergen Riegel

-

Form•Z from AutoDesSys, Inc

-

HiCAD from ISD Group

-

MicroStation from Bentley Systems

-

NX from Siemens PLM Software

-

Pro/ENGINEER from Parametric Technology Corporation

-

SALOME

-

S.FEM from HPESoft

-

Solid Edge from Siemens PLMSoftware

-

SolidWorks from SolidWorks Corp.

-

SpaceClaim Engineer from SpaceClaim Corp.

-

Tekla Structures from Tekla

-

TopSolid from Missler Software

-

TransMagic

-

VariCAD from VariCAD

-

VisualARQ from Asuni CAD S.A.

So you can open a DWG or other 3d file in one of the above 3D design Softwares and then you can easily convert your existing design to a .STEP file.

Converting the file is basically just opening your existing file and exporting it to your desired .STEP file in one of the 3D design software packages.

How do you convert a dwg to step file if you don’t have the softwares from the list above on your PC?

In general, this is an easy conversion if you have the software.

If you do not have any of the software packages then you can always try a trial version that you buy on trial.

You can then convert your files and cancel your account before the payment period starts.

Convert file from DWG to STEP file

If you really find all this too difficult or just don’t feel like it, then outsourcing this task is the best option.

There are lots of freelancer sites where engineers can convert your file to your desired format for a pinch.

Below are a few freelancer sites where you can have your files converted from DWG to .STEP format.

3D design and Engineering Forums

- CNCZone.nl (here you will find a lot of 3D Designers who would like to convert a file for you)

Find the right freelancer

Finding the right freelancer for your .DWG to .STEP file conversion is actually not that difficult at all.

All the above mentioned freelancer sites have a rating system by which all freelancers are rated.

So it is easy to find the right freelancer by searching for:

- someone with a lot of experience

- someone with good reviews

- someone who speaks your language or English

- Someone with the right training

If you want to know more about .step files and what the advantages are, check out the engineersrule.com website for a complete article.